About Storey Poultry Supplies Ltd.

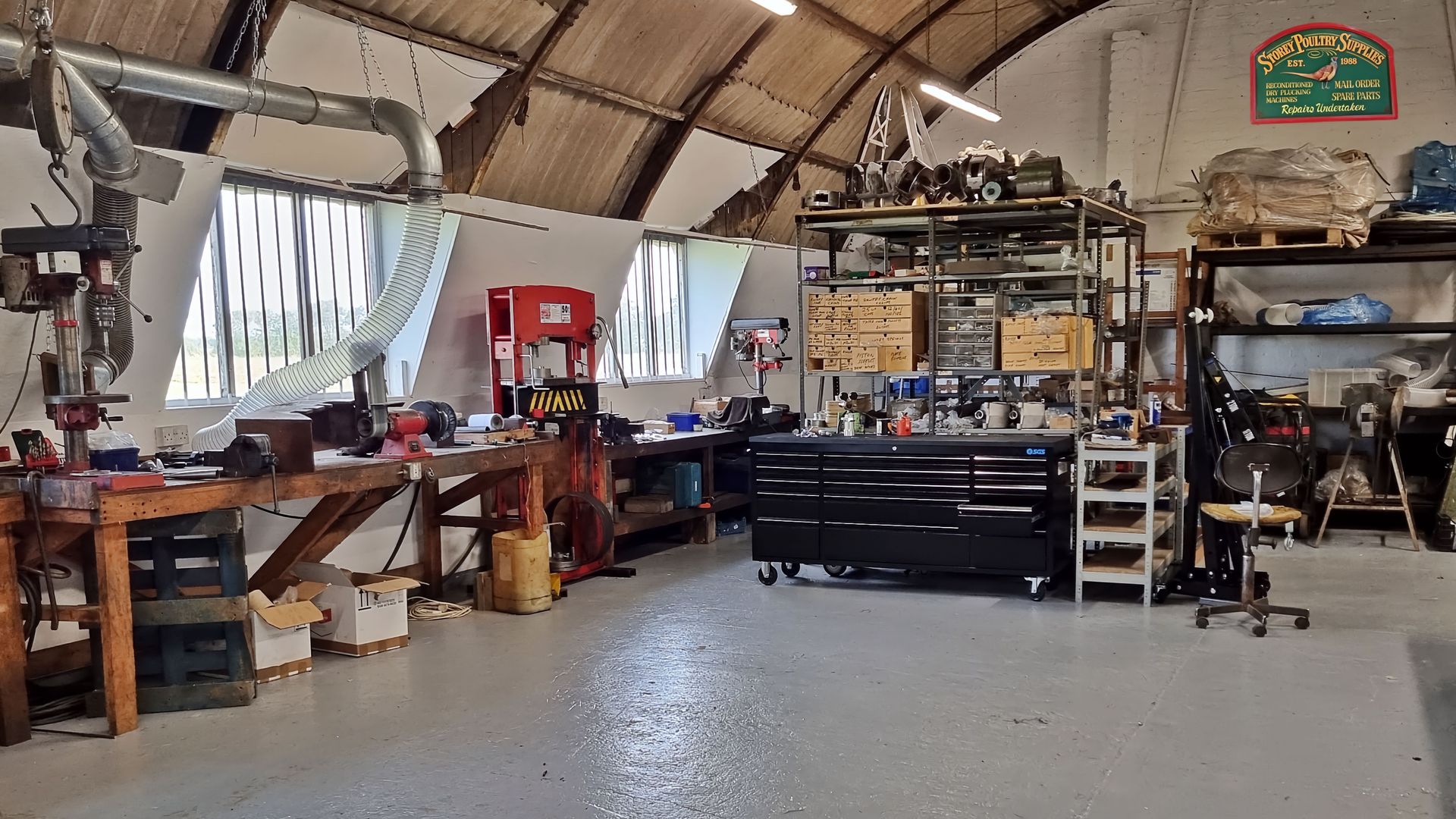

With over 3 decades in the industry and an undiminished passion, Storey Poultry Supplies Ltd offers the best possible option for anything relating to game & poultry processing equipment, spare parts, servicing and repairs.

Take a look at our company Storey!

We are a family run business with a rich history spanning over three decades.

We are located in the beautiful countryside of Suffolk in England, with an established and loyal customer base, nationwide.

We take great pride in our encyclopedic product knowledge and outstanding reputation for delivering exceptional customer service to game & poultry processors, of all sizes.

Take a look at our company Storey!

We are a family run business with a rich history spanning over three decades.

We are located in the beautiful countryside of Suffolk in England, with an established and loyal customer base, nationwide.

We take great pride in our encyclopedic product knowledge and outstanding reputation for delivering exceptional customer service to game & poultry processors, of all sizes.

We firmly believe in providing our customers with the same level of care and respect that we expect for ourselves, and this principle forms the foundation of our business... But where did it all start?

We firmly believe in providing our customers with the same level of care and respect that we expect for ourselves, and this principle forms the foundation of our business... But where did it all start?

So let's take a step back in time!

Where it all began...

Way back in the crisp autumn of 1982, as a 16 year old, I started working on a local farm before attending Writtle Collage. I convinced the the farmer to set two sheds aside for me, to indulge my childhood passion for poultry keeping... and so a life long career in the industry began!

Even before this, I had owned a small flock of laying hens , who's eggs I would sell to my teachers at school and to some of the friendly locals. But I had always fancied raising Guinea Fowl and so, whilst working on the local farm, I became the proud owner of fifty. I then had to think, who could I sell them to, but more importantly, how was I going to process them and get them to "oven ready" presentation...

My customers ranged from individuals to restaurants, hotels, and even wine bars. As repeat orders started pouring in, my flock grew to over 500 birds of different ages by the time I was nearing college.

The guinea fowl Enterprise was my introduction into plucking machines especially the dry plucking variety as I needed the bird to look good and offer a good shelf life. I was in the local young farmers at the time and one of my friends there gave me a Comb Classic that they hadn't used for years. I soon learned the plucking principle and understood the workings of the machine.

After winding down my guinea fowl enterprise, I embarked on my college journey. During the holidays, I would take on additional work to make some extra money by offering my services along with a plucking machine for others in need. It wasn't long before someone approached me, expressing their interest in purchasing a plucking machine alone. Intrigued, I decided to search for and acquire another machine. This trend continued with more people inquiring about buying machines, leading me to gradually venture into the business of hiring and refurbishing these machines.

During this time, I noticed a gap in the market for spare parts. The existing service in this particular area left much to be desired, prompting me to take matters into my own hands. Not only did I start manufacturing parts to meet my own needs, but I also aimed to provide the poultry industry with a range of spare parts made to higher quality standards using superior materials, catering to the needs of customers.

To where it all began...

Way back in the crisp autumn of 1982, as a 16 year old, I started working on a local farm before attending Writtle Collage. I convinced the the farmer to set two sheds aside for me, to indulge my childhood passion for poultry keeping... and so a life long career in the industry began!

Where it all began...

Way back in the crisp autumn of 1982, as a 16 year old, I started working on a local farm before attending Writtle Collage. I convinced the the farmer to set two sheds aside for me, to indulge my childhood passion for poultry keeping... and so a life long career in the industry began!

Even before this, I had owned a small flock of laying hens , who's eggs I would sell to my teachers at school and to some of the friendly locals. But I had always fancied raising Guinea Fowl and so, whilst working on the local farm, I became the proud owner of fifty. I then had to think, who could I sell them to, but more importantly, how was I going to process them and get them to "oven ready" presentation...

My customers ranged from individuals to restaurants, hotels, and even wine bars. As repeat orders started pouring in, my flock grew to over 500 birds of different ages by the time I was nearing college.

The guinea fowl Enterprise was my introduction into plucking machines especially the dry plucking variety as I needed the bird to look good and offer a good shelf life. I was in the local young farmers at the time and one of my friends there gave me a Comb Classic that they hadn't used for years. I soon learned the plucking principle and understood the workings of the machine.

After winding down my guinea fowl enterprise, I embarked on my college journey. During the holidays, I would take on additional work to make some extra money by offering my services along with a plucking machine for others in need. It wasn't long before someone approached me, expressing their interest in purchasing a plucking machine alone. Intrigued, I decided to search for and acquire another machine. This trend continued with more people inquiring about buying machines, leading me to gradually venture into the business of hiring and refurbishing these machines.

During this time, I noticed a gap in the market for spare parts. The existing service in this particular area left much to be desired, prompting me to take matters into my own hands. Not only did I start manufacturing parts to meet my own needs, but I also aimed to provide the poultry industry with a range of spare parts made to higher quality standards using superior materials, catering to the needs of customers.

To where it all began...

Way back in the crisp autumn of 1982, as a 16 year old, I started working on a local farm before attending Writtle Collage. I convinced the the farmer to set two sheds aside for me, to indulge my childhood passion for poultry keeping... and so a life long career in the industry began!

Where it all began...

Way back in the crisp autumn of 1982, as a 16 year old, I started working on a local farm before attending Writtle Collage. I convinced the the farmer to set two sheds aside for me, to indulge my childhood passion for poultry keeping... and so a life long career in the industry began!

Even before this, I had owned a small flock of laying hens , who's eggs I would sell to my teachers at school and to some of the friendly locals. But I had always fancied raising Guinea Fowl and so, whilst working on the local farm, I became the proud owner of fifty. I then had to think, who could I sell them to, but more importantly, how was I going to process them and get them to "oven ready" presentation...

My customers ranged from individuals to restaurants, hotels, and even wine bars. As repeat orders started pouring in, my flock grew to over 500 birds of different ages by the time I was nearing college.

The guinea fowl Enterprise was my introduction into plucking machines especially the dry plucking variety as I needed the bird to look good and offer a good shelf life. I was in the local young farmers at the time and one of my friends there gave me a Comb Classic that they hadn't used for years. I soon learned the plucking principle and understood the workings of the machine.

After winding down my guinea fowl enterprise, I embarked on my college journey. During the holidays, I would take on additional work to make some extra money by offering my services along with a plucking machine for others in need. It wasn't long before someone approached me, expressing their interest in purchasing a plucking machine alone. Intrigued, I decided to search for and acquire another machine. This trend continued with more people inquiring about buying machines, leading me to gradually venture into the business of hiring and refurbishing these machines.

During this time, I noticed a gap in the market for spare parts. The existing service in this particular area left much to be desired, prompting me to take matters into my own hands. Not only did I start manufacturing parts to meet my own needs, but I also aimed to provide the poultry industry with a range of spare parts made to higher quality standards using superior materials, catering to the needs of customers.

Let's take a step back in time!

To where it all began...

Way back in the crisp autumn of 1982, as a 16 year old, I started working on a local farm before attending Writtle Collage. I convinced the the farmer to set two sheds aside for me, to indulge my childhood passion for poultry keeping... and so a life long career in the industry began!

Even before this, I had owned a small flock of laying hens , who's eggs I would sell to my teachers at school and to some of the friendly locals. But I had always fancied raising Guinea Fowl and so, whilst working on the local farm, I became the proud owner of fifty. I then had to think, who could I sell them to, but more importantly, how was I going to process them and get them to "oven ready" presentation...

My customers ranged from individuals to restaurants, hotels, and even wine bars. As repeat orders started pouring in, my flock grew to over 500 birds of different ages by the time I was nearing college.

The guinea fowl Enterprise was my introduction into plucking machines especially the dry plucking variety as I needed the bird to look good and offer a good shelf life. I was in the local young farmers at the time and one of my friends there gave me a Comb Classic that they hadn't used for years. I soon learned the plucking principle and understood the workings of the machine.

After winding down my guinea fowl enterprise, I embarked on my college journey. During the holidays, I would take on additional work to make some extra money by offering my services along with a plucking machine for others in need. It wasn't long before someone approached me, expressing their interest in purchasing a plucking machine alone. Intrigued, I decided to search for and acquire another machine. This trend continued with more people inquiring about buying machines, leading me to gradually venture into the business of hiring and refurbishing these machines.

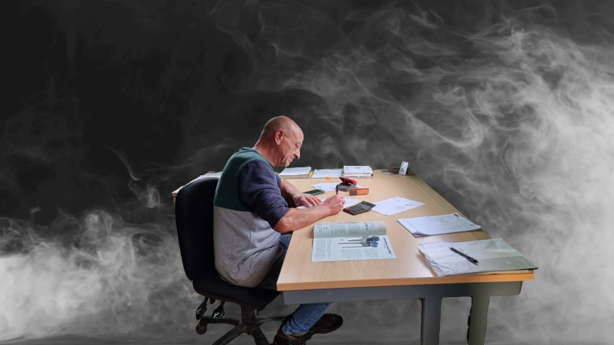

During this time, I noticed a gap in the market for spare parts. The existing service in this particular area left much to be desired, prompting me to take matters into my own hands. Not only did I start manufacturing parts to meet my own needs, but I also aimed to provide the poultry industry with a range of spare parts made to higher quality standards using superior materials, catering to the needs of customers.

Mark Storey

Where it all began...

Way back in the crisp autumn of 1982, as a 16 year old, I started working on a local farm before attending Writtle Collage. I convinced the the farmer to set two sheds aside for me, to indulge my childhood passion for poultry keeping... and so a life long career in the industry began!

Even before this, I had owned a small flock of laying hens , who's eggs I would sell to my teachers at school and to some of the friendly locals. But I had always fancied raising Guinea Fowl and so, whilst working on the local farm, I became the proud owner of fifty. I then had to think, who could I sell them to, but more importantly, how was I going to process them and get them to "oven ready" presentation...

My customers ranged from individuals to restaurants, hotels, and even wine bars. As repeat orders started pouring in, my flock grew to over 500 birds of different ages by the time I was nearing college.

The guinea fowl Enterprise was my introduction into plucking machines especially the dry plucking variety as I needed the bird to look good and offer a good shelf life. I was in the local young farmers at the time and one of my friends there gave me a Comb Classic that they hadn't used for years. I soon learned the plucking principle and understood the workings of the machine.

After winding down my guinea fowl enterprise, I embarked on my college journey. During the holidays, I would take on additional work to make some extra money by offering my services along with a plucking machine for others in need. It wasn't long before someone approached me, expressing their interest in purchasing a plucking machine alone. Intrigued, I decided to search for and acquire another machine. This trend continued with more people inquiring about buying machines, leading me to gradually venture into the business of hiring and refurbishing these machines.

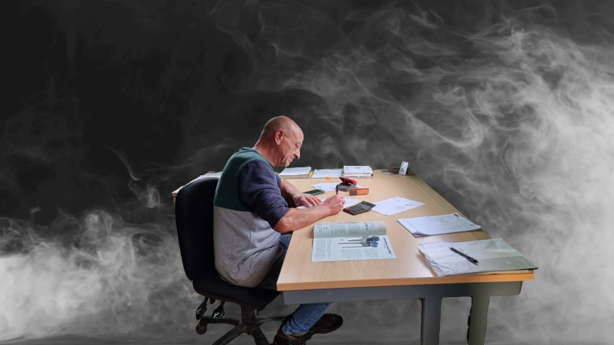

During this time, I noticed a gap in the market for spare parts. The existing service in this particular area left much to be desired, prompting me to take matters into my own hands. Not only did I start manufacturing parts to meet my own needs, but I also aimed to provide the poultry industry with a range of spare parts made to higher quality standards using superior materials, catering to the needs of customers.

Even before this, I had owned a small flock of laying hens , who's eggs I would sell to my teachers at school and to some of the friendly locals. But I had always fancied raising Guinea Fowl and so, whilst working on the local farm, I became the proud owner of fifty. I then had to think, who could I sell them to, but more importantly, how was I going to process them and get them to "oven ready" presentation...

My customers ranged from individuals to restaurants, hotels, and even wine bars. As repeat orders started pouring in, my flock grew to over 500 birds of different ages by the time I was nearing college.

The guinea fowl Enterprise was my introduction into plucking machines especially the dry plucking variety as I needed the bird to look good and offer a good shelf life. I was in the local young farmers at the time and one of my friends there gave me a Comb Classic that they hadn't used for years. I soon learned the plucking principle and understood the workings of the machine.

After winding down my guinea fowl enterprise, I embarked on my college journey. During the holidays, I would take on additional work to make some extra money by offering my services along with a plucking machine for others in need. It wasn't long before someone approached me, expressing their interest in purchasing a plucking machine alone. Intrigued, I decided to search for and acquire another machine. This trend continued with more people inquiring about buying machines, leading me to gradually venture into the business of hiring and refurbishing these machines.

During this time, I noticed a gap in the market for spare parts. The existing service in this particular area left much to be desired, prompting me to take matters into my own hands. Not only did I start manufacturing parts to meet my own needs, but I also aimed to provide the poultry industry with a range of spare parts made to higher quality standards using superior materials, catering to the needs of customers.

Mark Storey

Where it all began...

Way back in the crisp autumn of 1982, as a 16 year old, I started working on a local farm before attending Writtle Collage. I convinced the the farmer to set two sheds aside for me, to indulge my childhood passion for poultry keeping... and so a life long career in the industry began!

Even before this, I had owned a small flock of laying hens , who's eggs I would sell to my teachers at school and to some of the friendly locals. But I had always fancied raising Guinea Fowl and so, whilst working on the local farm, I became the proud owner of fifty. I then had to think, who could I sell them to, but more importantly, how was I going to process them and get them to "oven ready" presentation...

My customers ranged from individuals to restaurants, hotels, and even wine bars. As repeat orders started pouring in, my flock grew to over 500 birds of different ages by the time I was nearing college.

The guinea fowl Enterprise was my introduction into plucking machines especially the dry plucking variety as I needed the bird to look good and offer a good shelf life. I was in the local young farmers at the time and one of my friends there gave me a Comb Classic that they hadn't used for years. I soon learned the plucking principle and understood the workings of the machine.

After winding down my guinea fowl enterprise, I embarked on my college journey. During the holidays, I would take on additional work to make some extra money by offering my services along with a plucking machine for others in need. It wasn't long before someone approached me, expressing their interest in purchasing a plucking machine alone. Intrigued, I decided to search for and acquire another machine. This trend continued with more people inquiring about buying machines, leading me to gradually venture into the business of hiring and refurbishing these machines.

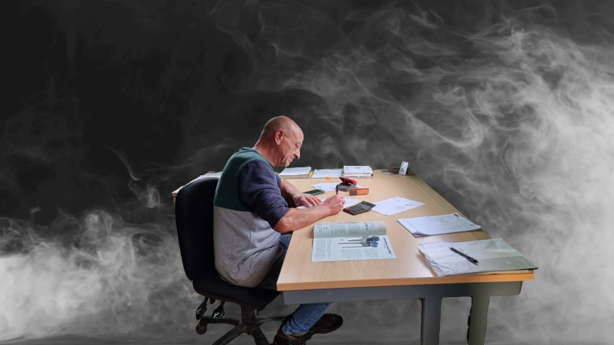

During this time, I noticed a gap in the market for spare parts. The existing service in this particular area left much to be desired, prompting me to take matters into my own hands. Not only did I start manufacturing parts to meet my own needs, but I also aimed to provide the poultry industry with a range of spare parts made to higher quality standards using superior materials, catering to the needs of customers.

Even before this, I had owned a small flock of laying hens , who's eggs I would sell to my teachers at school and to some of the friendly locals. But I had always fancied raising Guinea Fowl and so, whilst working on the local farm, I became the proud owner of fifty. I then had to think, who could I sell them to, but more importantly, how was I going to process them and get them to "oven ready" presentation...

My customers ranged from individuals to restaurants, hotels, and even wine bars. As repeat orders started pouring in, my flock grew to over 500 birds of different ages by the time I was nearing college.

The guinea fowl Enterprise was my introduction into plucking machines especially the dry plucking variety as I needed the bird to look good and offer a good shelf life. I was in the local young farmers at the time and one of my friends there gave me a Comb Classic that they hadn't used for years. I soon learned the plucking principle and understood the workings of the machine.

After winding down my guinea fowl enterprise, I embarked on my college journey. During the holidays, I would take on additional work to make some extra money by offering my services along with a plucking machine for others in need. It wasn't long before someone approached me, expressing their interest in purchasing a plucking machine alone. Intrigued, I decided to search for and acquire another machine. This trend continued with more people inquiring about buying machines, leading me to gradually venture into the business of hiring and refurbishing these machines.

During this time, I noticed a gap in the market for spare parts. The existing service in this particular area left much to be desired, prompting me to take matters into my own hands. Not only did I start manufacturing parts to meet my own needs, but I also aimed to provide the poultry industry with a range of spare parts made to higher quality standards using superior materials, catering to the needs of customers.

As the business moved forwards I bought many used dry plucking machines, completely refurbished them using spare parts made by myself, and sold them, they looked like the day they left the factory but were using superior components. This is where I built my reputation and led me to build more spare parts to service customers needs.

Mark Storey

MORE OF OUR SERVICES

New Equipment

We stock numerous leading brands and are recommended suppliers of Senesi and Bingham equipment.

Refurbished Equipment

We refurbish and re-sell high quality used equipment from many of the industries leading brands.

Spare Parts

We stock manufacturers, own brand and refurbished replacement parts for numerous plucking machines.

Servicing & Repairs

We service and repair a wide range of old and new equipment, drawing on years of industry knowledge.

WHERE TO FIND US

Unit 53C Notley Enterprise Park

Raydon Road

Great Wenham

Colchester

Essex CO7 6QD

© All rights reserved

All creative elements on this site are the intellectual property of WSEO